Wynn’s Commercial Vehicle DPF Regenerator & NOx Sensor Protector 1000ml has been developed to clear blocked particulate filters and reduce soot emissions in all diesel engines, also designed to protect the NOx sensor against soot build up and expensive replacements.

The NOx sensor is responsible for measuring the vehicles NOx (Nitrous Oxides) levels produced following the combustion cycle.

Most diesel engines have 2 sensors, an upstream and downstream sensor, their role is to monitor the performance and ensure the system isn’t producing too much excess gases, which are harmful to the environment and public health. Controlling these emissions would not be possible without the sensors making their use very important.

The first NOx sensor is near the turbo down pipe and measures the NOx coming out of the engine, the second sensor measures NOx exiting the SCR catalyst, the catalyst is the last check before the emission are passed out of the exhaust. The SCR assembly contains a catalyst and require DEF (Diesel Exhaust Fluid) better known as AdBlue® for activation.

What does AdBlue® do?

The AdBlue® is introduced into the catalyst by a pump and injector controlled by the engine management system. Using the heat from the exhaust gases the AdBlue® will convert to ammonia and carbon dioxide. If too much AdBlue® is injected into the SCR catalyst it can become saturated with Ammonia, this is often referred to as Ammonia Slip. To a NOx sensor ammonia and NOx look the same, this will report an incorrect amount of NOx in the system.

AdBlue® has a shelf life of about 12 months before it starts to crystallise and crystallisation can also cause a reduction in NOx conversion and affect the sensor.

NOx sensors in commercial vehicles are extremely important and can often cost several thousand pounds in replacement and vehicle down time, so regular use of DPF regenerator and NOx sensor protector can help to protect this. The system needs to reach temperature of about 600 degrees to self clean, but using the fluid can reduce this temperature to 350 allowing better regeneration and soot burn off. This lower temperature helps to burn water and moisture content inside the system.

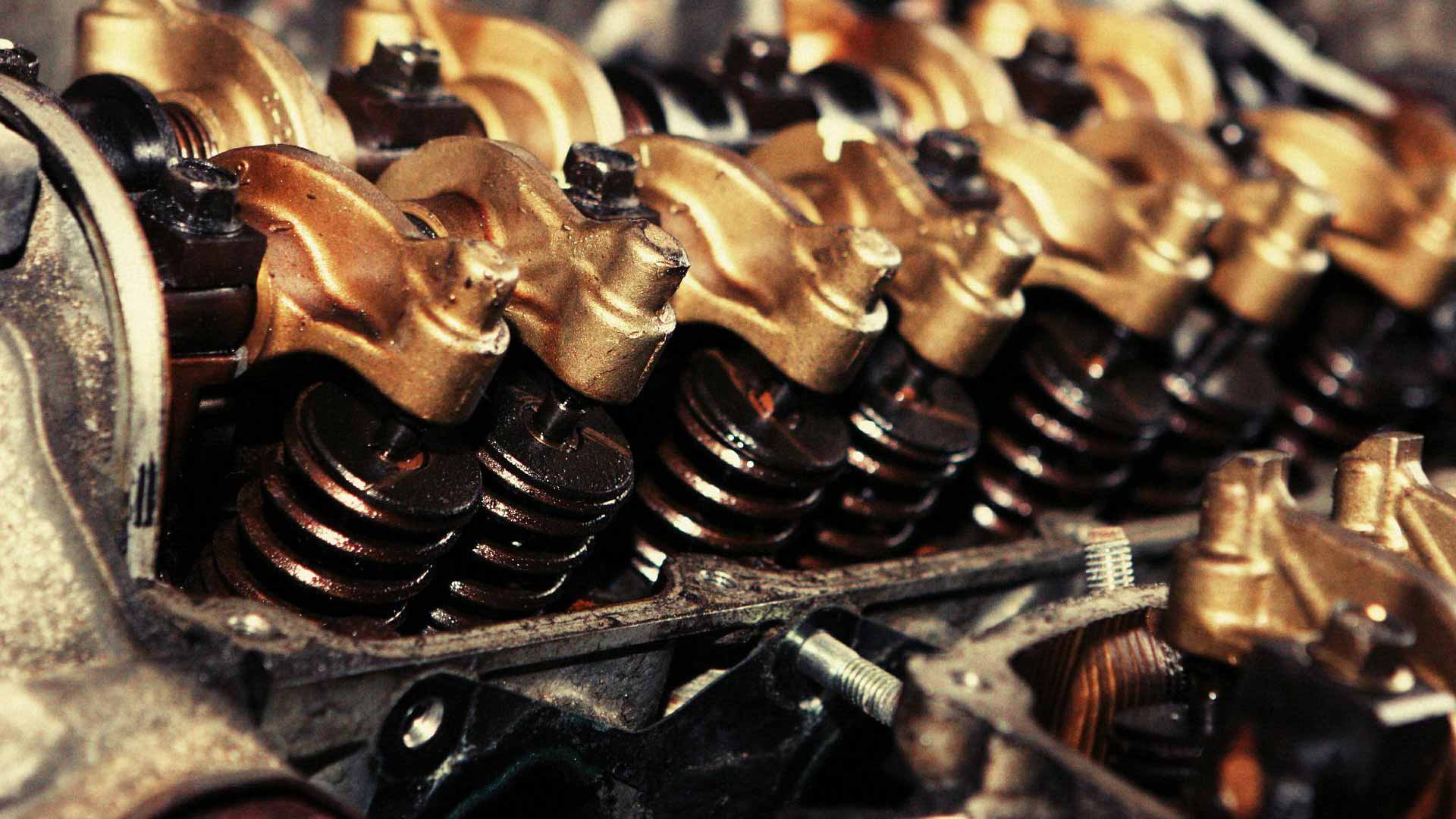

What causes a sensor to fail:

- Water in the exhaust system

- Injector fouling, injector leaking, engine misfire

- Soot from combustion process can coat the sensor

- Soot is abrasive and can damage the sensor

- Impact damage – objects from road surface hitting sensor

- Increased oil consumption, oil entering he exhaust system

Directions

- Add 1 litre of additive to minimum of 75 litres of fuel

- 1 litre will treat 500 litres of fuel

- Use every 6000 miles if a lot of stop start journeys